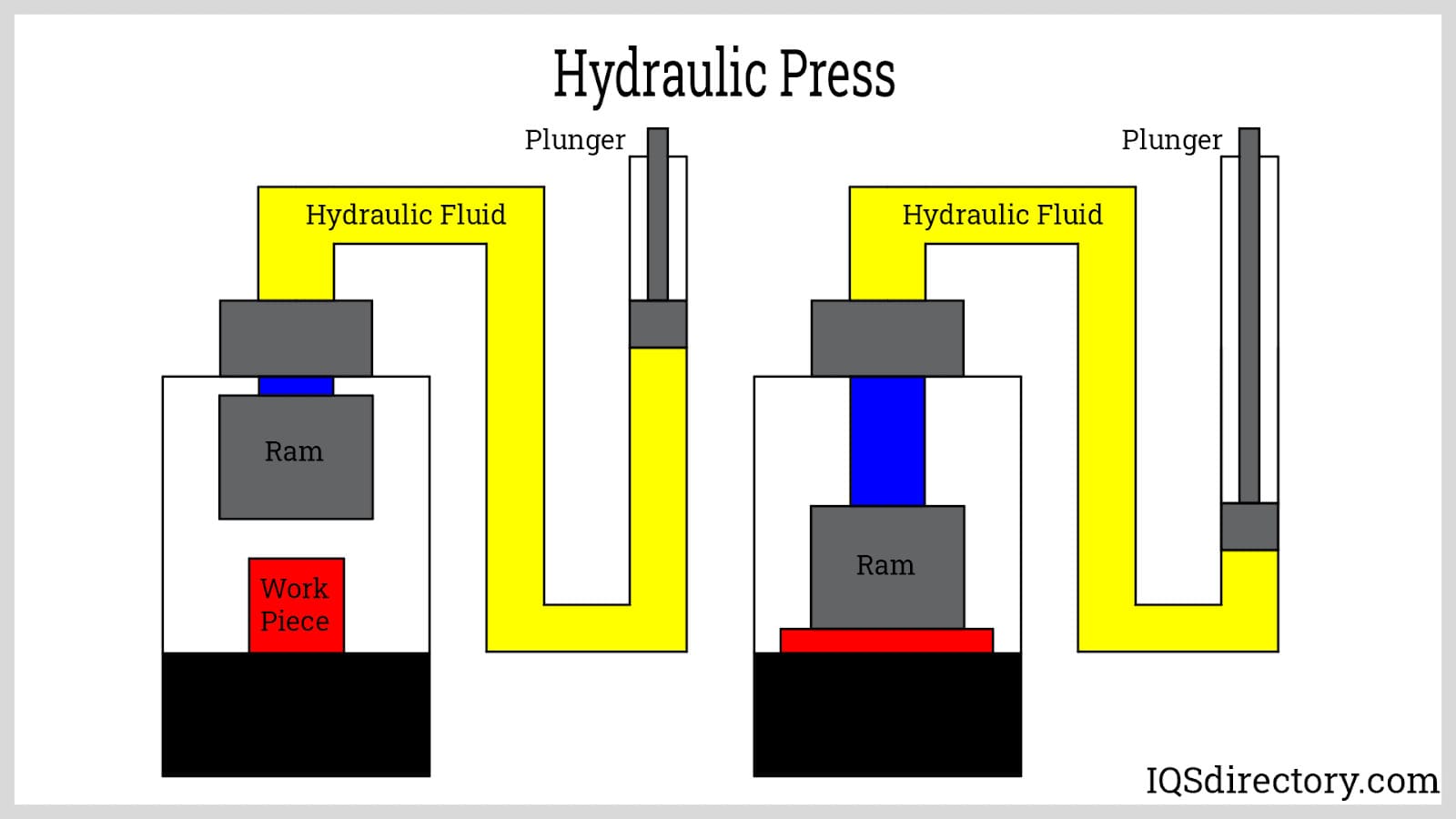

A press is a type of machine of which there are many kinds; however, in its most basic form a press is a machine that uses pressure in order to exert force upon an object. The three main types of pressure that presses utilize are mechanical, hydraulic and pneumatic pressure. Read More…

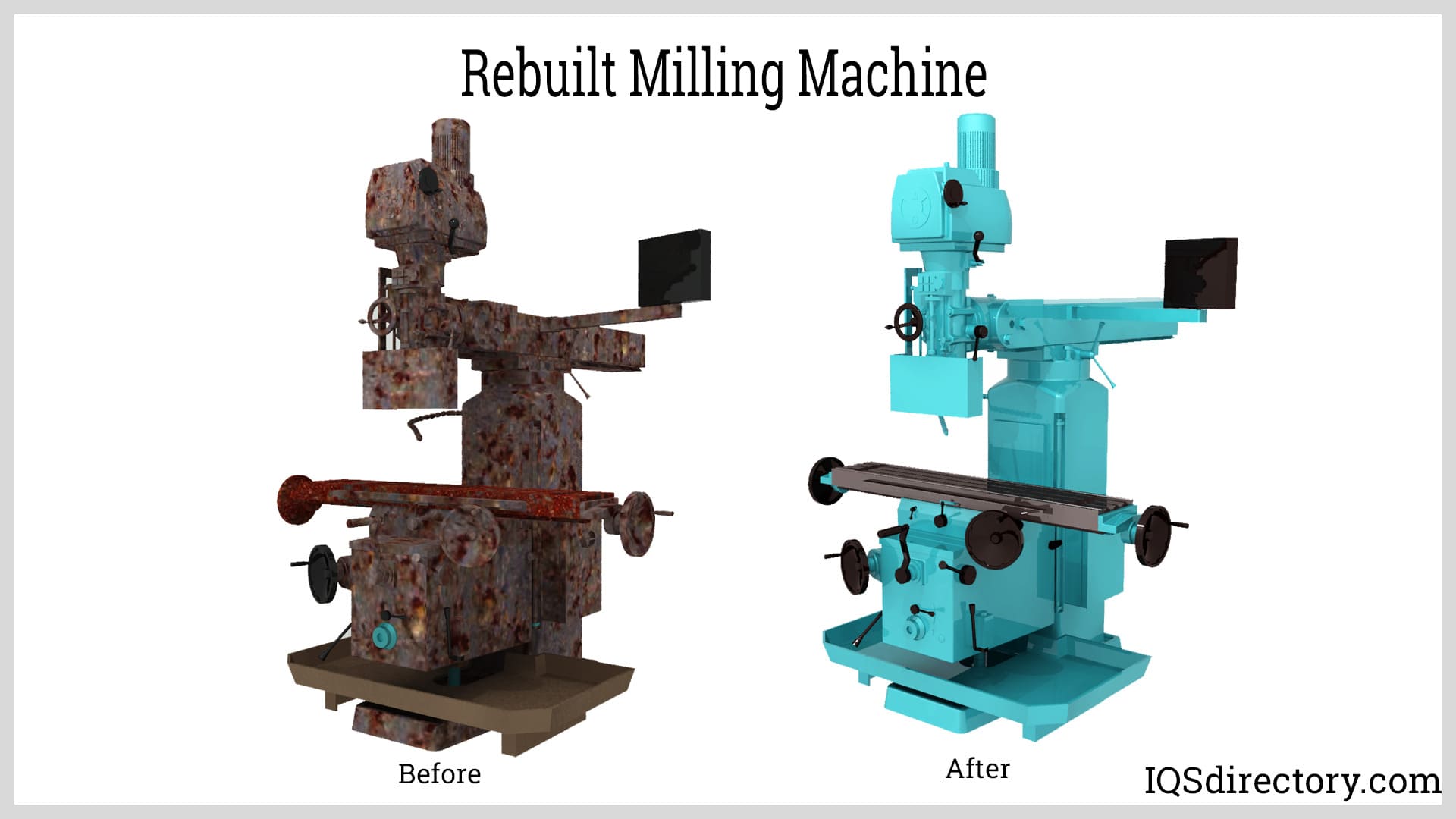

If you need to get your critical system back up and running again as quickly as possible, Precision Service Machine Tool Rebuilders, Inc. has what you need. Since 1983, Precision Service MTR has been a reliable and trusted resource in the field of industrial machinery repair. Our highly skilled service technicians offer custom rebuilding strategies, onsite repair, and unmatched service.

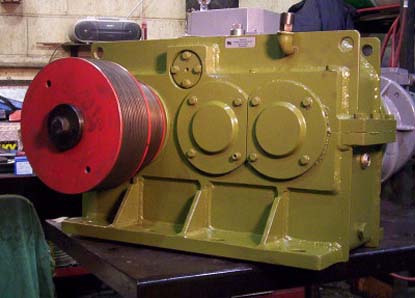

At Lindquist Machine Corporation, we take pride in our role as machinery rebuilders, dedicated to providing exceptional solutions to our valued clientele. With a rich history of expertise and dedication to quality, innovation, and customer satisfaction, we have established ourselves as a trusted partner in the industry. Our core focus lies in rebuilding a wide range of machinery, including CNC...

We are machinery rebuilders specializing in press rebuilding and repair plus clutch rebuilding and conversion. Our machine shop repairmen average 25 to 35 years of experience with all types of metalforming and manufacturing equipment. We can provide on-site service including new part fabrication.

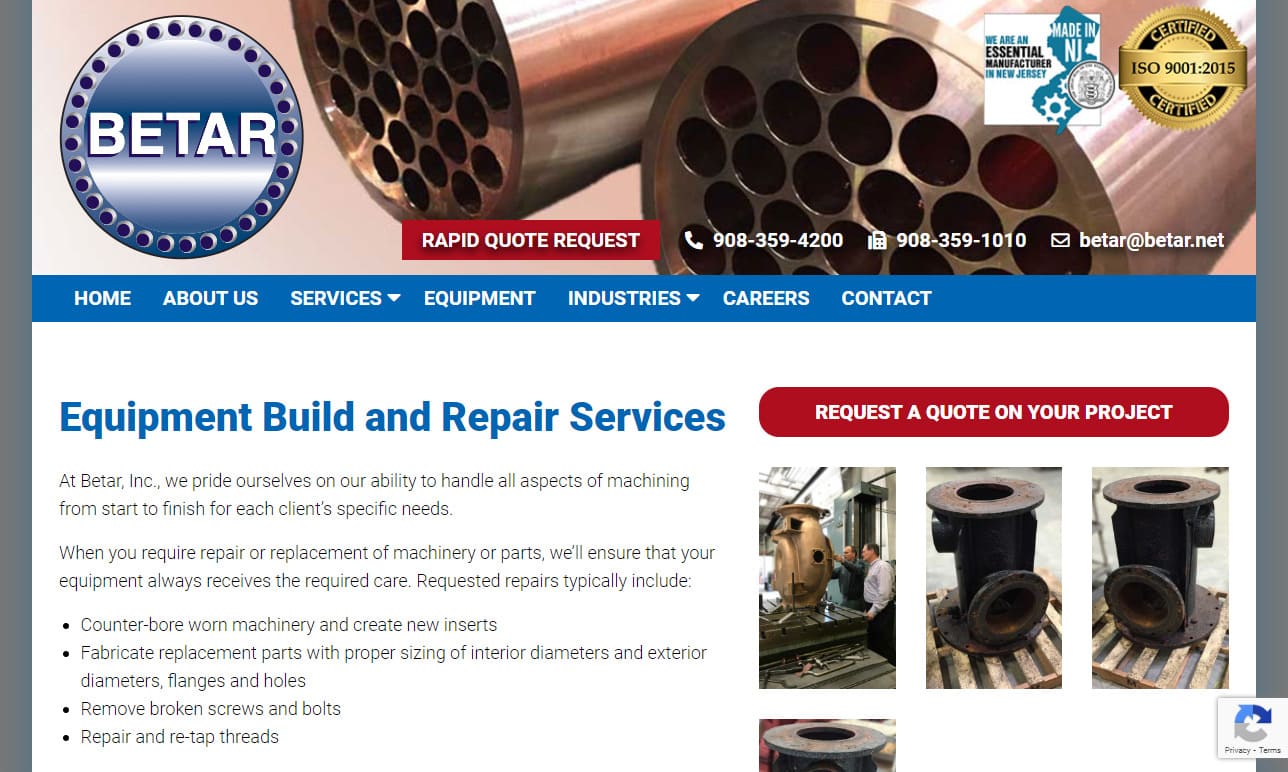

At Betar, Inc., we pride ourselves on being expert machinery rebuilders, dedicated to providing top-tier solutions to our valued clientele. With a wealth of industry experience and a steadfast commitment to quality, innovation, and customer satisfaction, we have cemented our reputation as a trusted partner in the realm of machinery repair and refurbishment. Our primary focus revolves around the...

Welcome to Benning, where we specialize in rebuilding, repair, retrofitting, hand scraping and service on all types of precision metal working equipment. We provide services at our place or yours and machine size is never a factor. Some of the services available are spindle grinding, way surface repair, complete leveling service and much more. We’ve been servicing machine tools since 1972.

More Press Repair Companies

In addition to repair work, press repair service companies often provide rebuilding/remanufacturing, retrofitting and refurbishing services as well. Some examples of press problems that would require repair services include worn or broken cylinders and valves, worn seals and hoses, broken shaft and other damaged components such as through liners and wiper rings.

Essential to many applications, press repair companies offer a valuable service to industries such as: printing, in which the repair of worn or damaged printing presses is crucial; industrial, for the repair of presses such as hydraulic presses, C-frame presses and more that are vital to many manufacturing applications such as metal stampings; automotive, which utilizes presses in the manufacturing of numerous auto parts such as hubs, fenders and various body parts; and textile, which utilizes presses such as calendaring heat presses and letter printing presses.

Some of the most common types of presses that press repair service companies work with include stamping presses, brake presses and forging presses. An often used machine in the industrial manufacturing industry, stamping presses are defined as devices that are designed and built to operate one or multiple progressive stamping dies and other types of dies as well.

Stamping presses are such a popular type of press because they have the ability to fulfill almost any metal forming or stamping need. Brake presses, on the other hand, are defined as devices that are used to make bends or folds in sheet metal by means of pressing them into dies through a cold working process. Also known as press brakes, brake presses can be manually-operated, but are typically either semi-automatic or fully automatic.

Lastly, forging presses are also extremely common in the industrial manufacturing industry. Forging presses are defined as devices that are typically hydraulically-powered, and are a type of metal forming machinery that force metal blocks to take the shape of a product by means of a mold, extreme force and pressure, and sometimes heat. Forging presses are often used as an alternative to hammer and rolling forging, and by utilizing two press rams that move together in a linear motion, forging presses are able to produce up to 50 thousand tons of force at one time.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services