A gearbox is defined as a mechanical device that houses a set of gears as well as input and output shafts. The purpose of a gearbox is to reduce the speed of the motor by means of increasing torque while decreasing output speed. Read More…

If you need to get your critical system back up and running again as quickly as possible, Precision Service Machine Tool Rebuilders, Inc. has what you need. Since 1983, Precision Service MTR has been a reliable and trusted resource in the field of industrial machinery repair. Our highly skilled service technicians offer custom rebuilding strategies, onsite repair, and unmatched service.

At Lindquist Machine Corporation, we take pride in our role as machinery rebuilders, dedicated to providing exceptional solutions to our valued clientele. With a rich history of expertise and dedication to quality, innovation, and customer satisfaction, we have established ourselves as a trusted partner in the industry. Our core focus lies in rebuilding a wide range of machinery, including CNC...

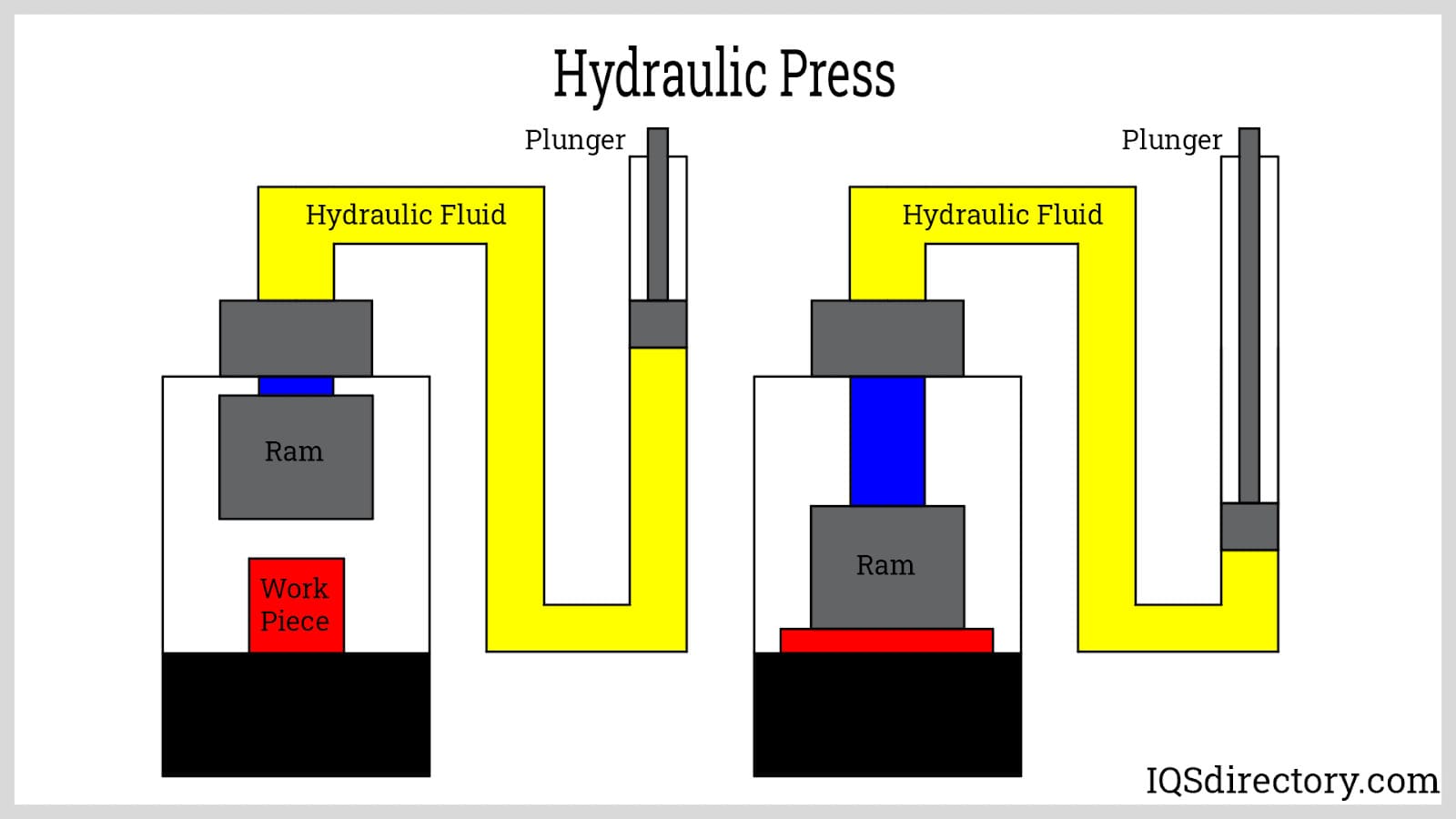

We are machinery rebuilders specializing in press rebuilding and repair plus clutch rebuilding and conversion. Our machine shop repairmen average 25 to 35 years of experience with all types of metalforming and manufacturing equipment. We can provide on-site service including new part fabrication.

At Betar, Inc., we pride ourselves on being expert machinery rebuilders, dedicated to providing top-tier solutions to our valued clientele. With a wealth of industry experience and a steadfast commitment to quality, innovation, and customer satisfaction, we have cemented our reputation as a trusted partner in the realm of machinery repair and refurbishment. Our primary focus revolves around the...

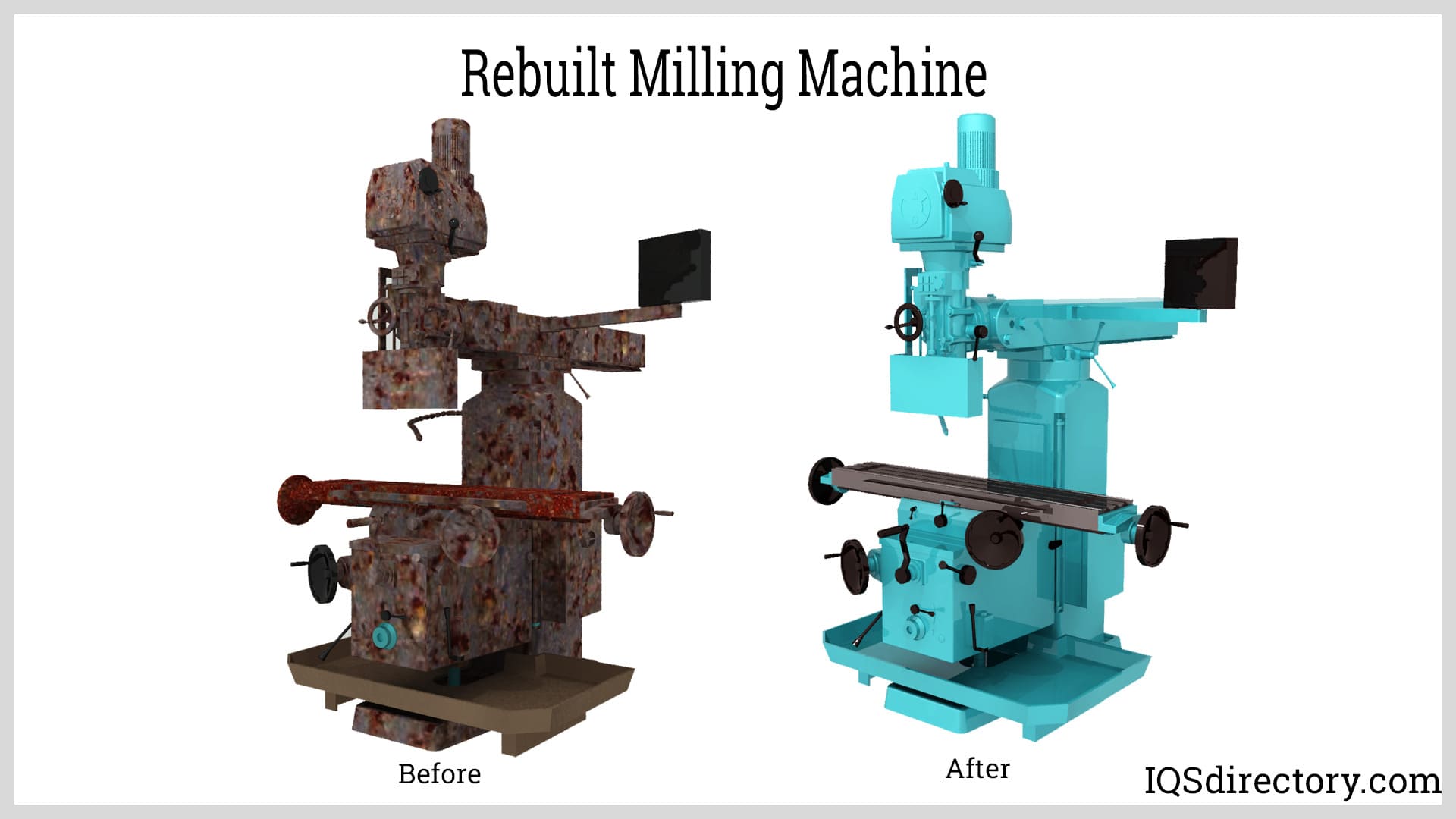

Welcome to Benning, where we specialize in rebuilding, repair, retrofitting, hand scraping and service on all types of precision metal working equipment. We provide services at our place or yours and machine size is never a factor. Some of the services available are spindle grinding, way surface repair, complete leveling service and much more. We’ve been servicing machine tools since 1972.

More Gearbox Repair Companies

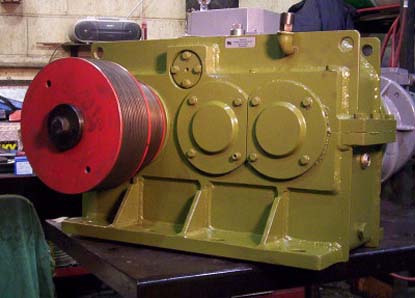

Often referred to as gear heads, gear boxes are a common type of speed reducer and a crucial to a number of applications. As a result, gearbox repair services are often required in a wide range of industries including: automotive, in which gear boxes are used in many types of vehicles for power transmission applications; industrial manufacturing, for use in automation equipment such as conveyors, compressors and pumps; marine, in order to reduce and thus, control the speed of engine-driven shipping vessels; aerospace, for use in the speed control of engines in aircrafts such as helicopters and military airplanes; and petroleum, in order to be used in various types of oil and gas pumps.

Gearbox repair services are also essential for industries such as printing, textile, food and beverage, construction, mining and power generation.

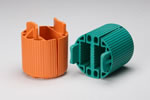

Gearbox repair service companies enable gearboxes to have an increased service life as well as increased efficiency. Gearboxes can include a set of many different types of gears, the most common of which in industrial-type settings include spur gears, helical gears, planetary gears, miter gears, rack and pinion gears, worm gears and bevel gears. In addition, many gear box repair service companies also provide repair services for sprockets and splines, which are very closely related to gears.

Some typical issues that result in the requirement of gearbox repair services include transmission fluid leakage, gear slipping (most common in the automotive industry), overheating and surging of the transmission. In order to address many of these issues, and bring the gearboxes back to the quality standards achieved during their original manufacturing, gearbox repair service companies offer a diverse range of capabilities including stress analysis, cleaning, refurbishing, painting, assembly and teardown.

Additional services that they may offer include hobbing, grinding and shaping of the gearboxes. Some of the quality standards that gearbox repair service companies finished and repaired products must meet include original equipment manufacturers (OEM) standards and the American Gear Manufacturers Association (AGMA) standards.

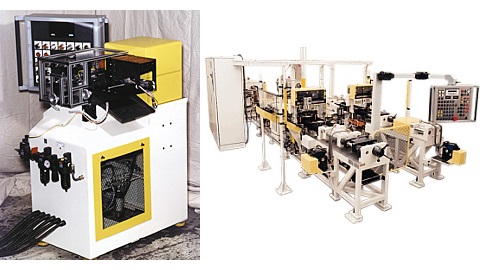

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services