The term “machinery rebuilders” is a label that has been largely replaced by the now-common “remanufacturer.” Both terms, however, are valid. They refer to service companies that replace and/or take apart, clean, and repair different machines and machine parts. The goal of machinery rebuilders is to increase equipment life and, occasionally, provide preventative maintenance. Read More…

If you need to get your critical system back up and running again as quickly as possible, Precision Service Machine Tool Rebuilders, Inc. has what you need. Since 1983, Precision Service MTR has been a reliable and trusted resource in the field of industrial machinery repair. Our highly skilled service technicians offer custom rebuilding strategies, onsite repair, and unmatched service.

At Lindquist Machine Corporation, we take pride in our role as machinery rebuilders, dedicated to providing exceptional solutions to our valued clientele. With a rich history of expertise and dedication to quality, innovation, and customer satisfaction, we have established ourselves as a trusted partner in the industry. Our core focus lies in rebuilding a wide range of machinery, including CNC...

We are machinery rebuilders specializing in press rebuilding and repair plus clutch rebuilding and conversion. Our machine shop repairmen average 25 to 35 years of experience with all types of metalforming and manufacturing equipment. We can provide on-site service including new part fabrication.

At Betar, Inc., we pride ourselves on being expert machinery rebuilders, dedicated to providing top-tier solutions to our valued clientele. With a wealth of industry experience and a steadfast commitment to quality, innovation, and customer satisfaction, we have cemented our reputation as a trusted partner in the realm of machinery repair and refurbishment. Our primary focus revolves around the...

Welcome to Benning, where we specialize in rebuilding, repair, retrofitting, hand scraping and service on all types of precision metal working equipment. We provide services at our place or yours and machine size is never a factor. Some of the services available are spindle grinding, way surface repair, complete leveling service and much more. We’ve been servicing machine tools since 1972.

More Machinery Rebuilding Companies

Machinery rebuilders generally work out of machine shops. There, they have access to countless machine tools and machine shop equipment. With them, they perform a myriad of services related to equipment repair and machine rebuilding/machine tool rebuilding.

Machinery rebuilders service the parts and products used in a wide variety of industries, including automotive, computer electronics, photography, industrial manufacturing, textiles, green energy, and printing.

Machinery rebuilders service products and product components all across the board, from heavy equipment to small electronic parts. Machine rebuilders repair, rework, and overhaul many different types of components, products, machines, and machine tools.

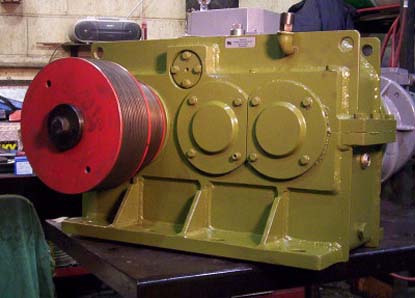

In industrial manufacturing, for example, some of the items that machine rebuilders most often repair and rebuild include presses, pumps, and tools. Some other parts and products that machinery rebuilders repair a little less often include gearboxes, spindles, ball screws, and lathes.

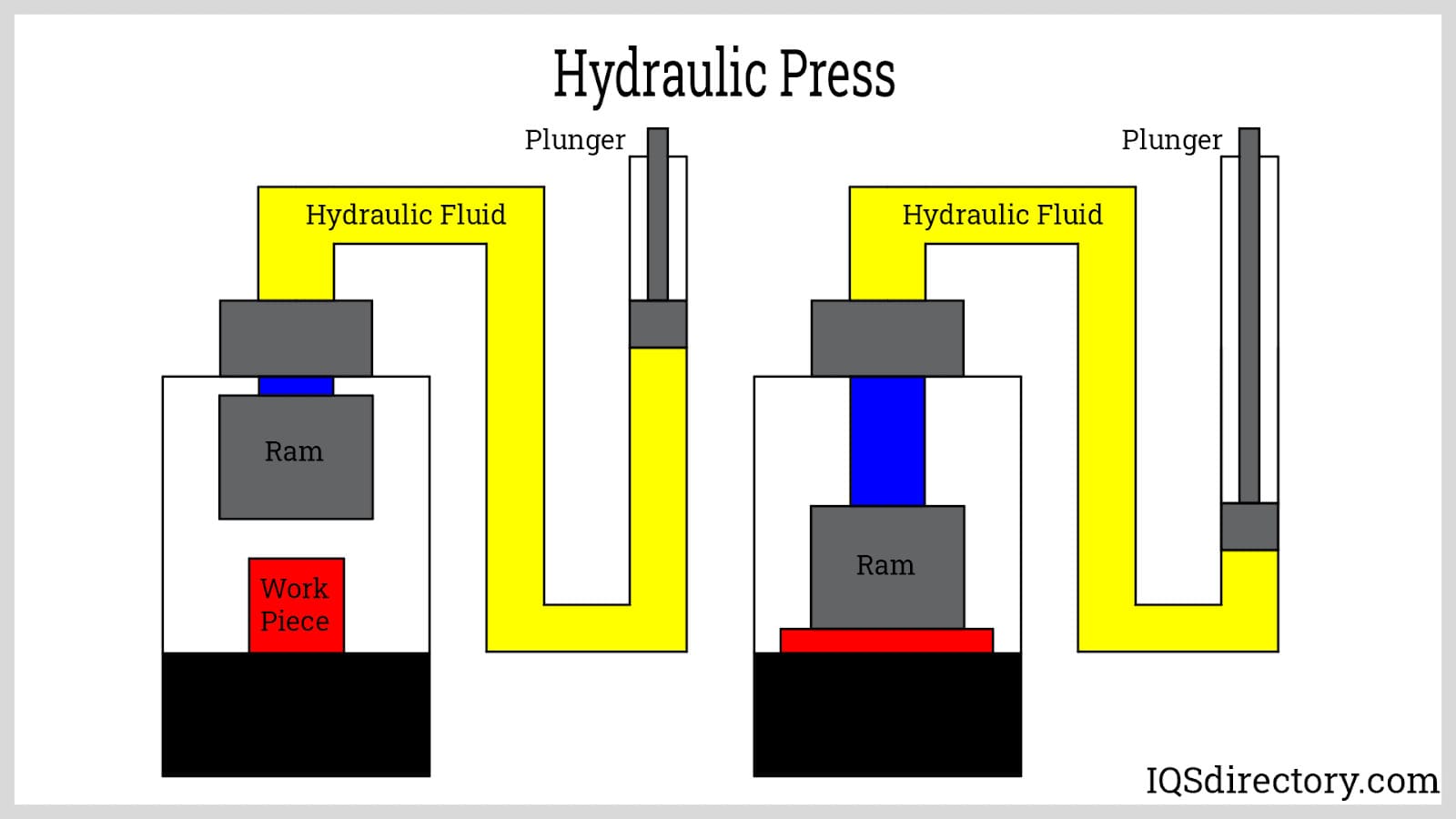

Presses that machinery rebuilders service includes any equipment or industrial machinery used to exert force or pressure onto a part or material. There are quite a few different types of industrial presses, but some that often need press repair include C presses, hydraulic presses, mechanical presses, printing presses, and stamping presses.

Pump repair services are a somewhat broader category that covers a wide range of pump configurations, such as centrifugal pumps, hydraulic pumps, metering pumps, and vacuum pumps. Basically, if a device or machine is used to transfer, compress, or raise fluids, it qualifies as a pump and is eligible for pump repair services.

Tools that fall under tool repair or machine tool repair and machine tool rebuild services are any devices that people use to facilitate or execute either mechanical or manual tasks. As such, machinery rebuilders can perform tool repairs on just about anything, from pressure sensors to power machine tools.

Gearboxes are the protective metal casings in which gear systems are housed for their protection. Gearbox services are important to many industries, but they are especially important to aerospace, automotive, and industrial manufacturing applications. Due to the many different gearbox styles, like spur, helical, and planetary, and the consequential differences in the boxes that hold them, gearbox repair services can be quite broad as well.

Spindles are pins or rods, tapered at one end and weighted on the other by a disc or spherical object called a whorl. They may also be accessorized with a hook, notch, or groove at the top, which helps guide yarn. Spindles are used to hand-spin and twist fiber into yarn. Spindle repair and spindle rebuilding services are not very extensive, but they are important to the textile industry.

Ball screw repairs, on the other hand, are a frequently sought-after service. Ball screws are mechanical linear actuators that transform rotational movement into linear motion. Because they require a lot of care to maintain efficiency, ball screw servicers are likely to have a good amount of business.

Lathes are machines that manufacturers use to shape materials as they rotate on the machine. While on the machine, the workpiece will encounter all sorts of cutting, machining, grinding, and shaping tools. Lathe repair keeps lathes working like new. Some of the lathe types that machinery rebuilders can service include multi-spindle lathes, toolroom lathes, CNC lathes, turret lathes, and grinding lathes (grinders).

History

Modern machinery rebuilding services got their start in the United States between the 1920s and 1930s. Machinery rebuilding became popular first as standardization offered the possibility of parts replacement (e.g. bearings), engine repair, and refurbished products. During the Great Depression, machinery rebuilding maintained its popularity because people simply did not have enough money to buy new appliances or cars. Machinery rebuilding, like engine rebuilding, offered consumers a more affordable alternative to attempting to finance a new product or attempting to go without one.

Aware of the trend, Henry Ford established the first American car engine rebuilder plant in 1932. Then, during World War II, the American government commissioned the remanufacturing of ships, airplanes, and military vehicles like tanks. After World War II, though the economy recovered, people continued to seek out machinery rebuilding as a smart and frugal choice.

Machinery rebuilding became important during the 1970s for a different reason. This was the decade that citizens woke up to the reality of their carbon footprint and the impact their actions had on the earth. As people sought to be more environmentally-friendly, they naturally gravitated towards remanufactured goods, which recycled resources and preserved energy. To appeal to their customers, more manufacturers in turn sought out manufacturing services like machine tool rebuilding.

The industry only got more popular as the decades of the 20th century wore on. In 1995, after the EPA published their CPG (Comprehensive Procurement Guideline) program, manufacturers sought out the services of machinery rebuilders even more heavily. The CPG program outlined ways of recycling and recovering solid waste for new production, waste reduction, and general conservation. It included a list of both required and incentivized products and materials that manufacturers could recycle or recover. Nine years after they first published the list, the EPA added rebuilt vehicular parts, giving automotive manufacturing yet another reason to seek out machinery rebuilding services.

Today, environmentalism and waste reduction are more important to consumers than ever. Naturally, the machinery rebuilding industry is therefore booming. We expect that in the future, as we must become more and more strict with our use and disposal of research, this trend will continue.

Service Details

Broadly, machinery rebuilding services follow this sequence: inspection, disassembly, cleaning, replacement or restoration, reassembly, and quality testing.

However, machinery rebuilders offer three main types of rebuilding: repair, rebuilding/remanufacturing, and retrofitting. Each presents a different level of rebuilding.

Repair services restore a machine either by replacing a malfunctioning part or putting back together a ripped or broken part. Repair services can be viewed as a short-term solution or a quick fix. They do not address the long-term needs of a machine.

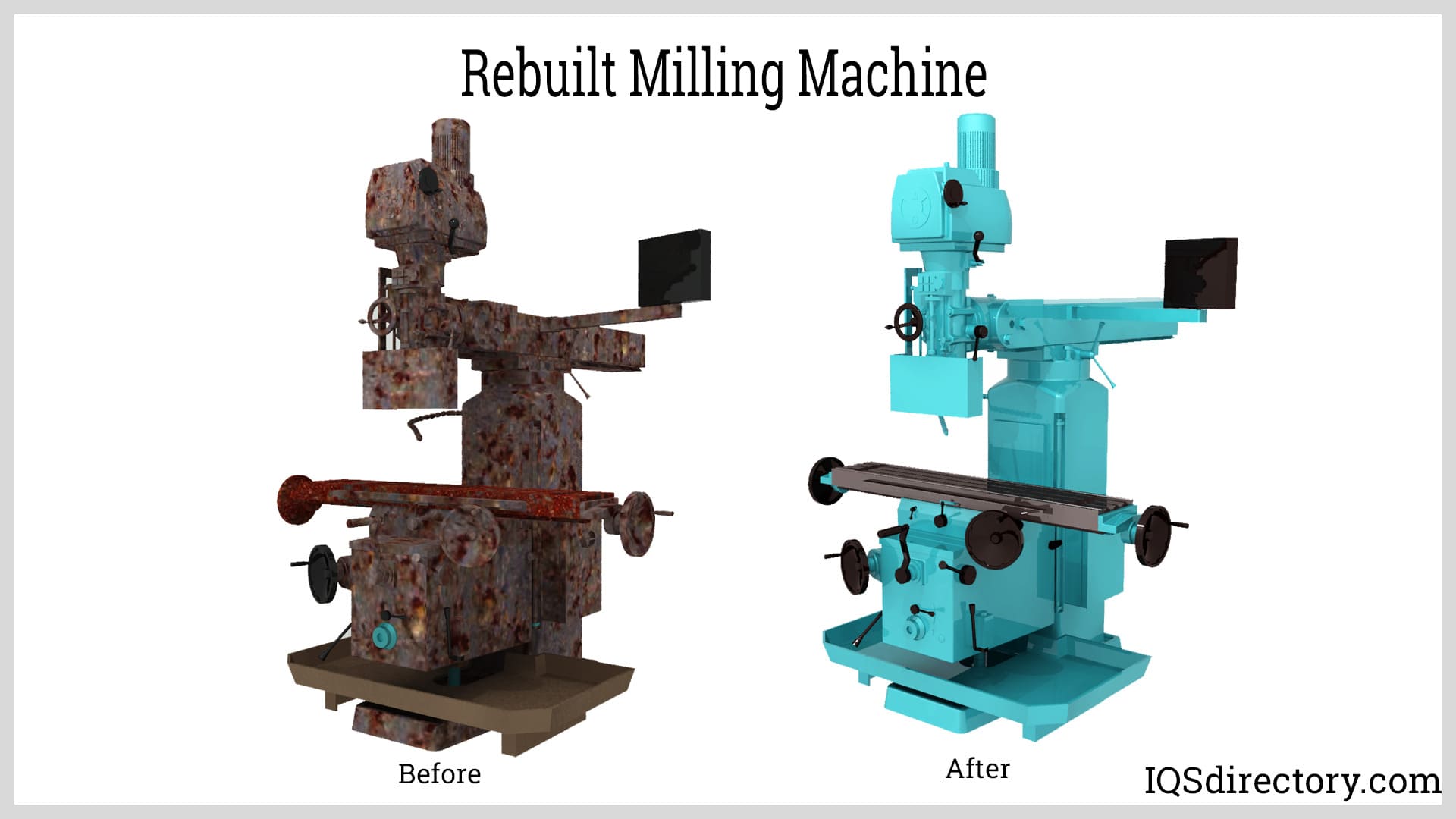

Rebuilding/remanufacturing services offer machine owners a more complete transformation or overhaul. These involve the disassembly and recovery of a piece of equipment or a machine. Recovery starts at the module level and eventually graduates to the component level. In other words, remanufacturing services are not done until a machine or machine part is completely restored to its original state. This commitment to quality is the reason that refurbished machines usually offer such comparable performances and service lives to brand new machines.

Retrofitting is an updating service used to provide equipment with devices, product components, or technology that were either not available or not common when the equipment was first manufactured.

Design

Before repairing, rebuilding, or retrofitting machinery, machinery rebuilders have to go over some details. First, they must consider the customer goals. Second, they must consider how they will reach these goals within their customer’s budget.

Based on their considerations, a machinery rebuilding team will then plot out their plan from start to finish. They may engage in any number of machining processes to bring the machinery to a rebuilt and like-new state. Examples include demanufacturing (disassembly of parts for recycling), parts replacement, counterbalancing, parts retooling, parts reorientation, material restoration and strengthening (coating, polishing, painting, buffing, reconditioning, etc.), deep cleaning, and more.

Machinery Used

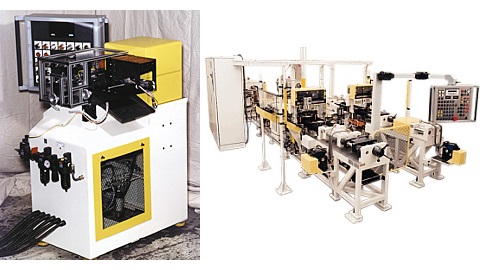

During the various machinery rebuilding processes, service providers use machine tools and machinery such as milling machines, CNC machines, injection molding machines, grinders, blow molding machines, and CNC screw machines.

Variations and Similar Processes

Machinery rebuilders break down rebuilding and remanufacturing service styles into three main groups: rebuilding without identity loss, repetitive rebuilding without identity loss, and rebuilding with the loss of the original product identity.

Rebuilding without identity loss is a method during which customers can expect that the machine body will be fully inspected for soundness, its modules will be updated, overhauled, or replaced, any machine defects will be corrected, and their equipment to come back to them like new. Like new means that the machine will have the expected life and warranty of a brand-new machine.

Repetitive rebuilding without identity loss is like the process before it, but with the added element of scheduling the sequence of dependent processes and identifying the location of inventory buffers. Note that this process is close to but does not quite involve a full equipment overhaul.

Rebuilding with the loss of the original product identity involves disassembling used products, refurbishing their parts, and then dividing them into inventoried groups. Once grouped, machinery rebuilders are ready to be reassemble them into a remanufactured product.

Benefits

Machinery rebuilders providers do an important job that has many benefits. By fixing machines and refurbishing machines, machine rebuilders not only help businesses save money, but help the environment as they reuse and recycle resources and help equipment run more efficiently.

In addition, remanufacturing contributes to the affordability and health of all sorts of machines, from Nintendo and other gaming machines, to air conditioning units, to bakery equipment, to engines, to hydraulic systems.

Things to Consider

Machinery rebuilders offer excellent services. Paired with the right contract manufacturer, you will be able to get many more years of valuable service out of your machinery. Paired with the wrong contract manufacturer, and you may end up with a malfunctioning system and a deficit in your books. To help you find a machinery rebuilding company that you can trust, we have listed some of those that we have found to be the most reliable. Check out the various profiles of these equipment rebuilders by scrolling up.

Before you scroll up, though, we suggest you take the time, if you have not done so already, to write down your application specifications. Don’t forget to write down your standard requirements, your budget, your delivery preferences, and your delivery deadline. Once you have done that, start browsing. You can quickly eliminate some contenders by comparing their offered services to the ones you have written on your list. Eliminate more until you’ve got three or four top picks.

From here, give each of them a call or send quote request. Make sure you get all the answers you need from each of them. If a customer service representative is not patient or does not want to answer your questions, pass on them. A considerate staff is one of the most important features of any supplier, no matter the industry. Once you have spoken with each potential service supplier, compare and contrast their quotes, and pick the supplier you believe will best serve you.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services