Some factors to consider when choosing a machine tool repair company include its experience in the business, the types of machine tools they repair, and the company’s reputation. Read More…

If you need to get your critical system back up and running again as quickly as possible, Precision Service Machine Tool Rebuilders, Inc. has what you need. Since 1983, Precision Service MTR has been a reliable and trusted resource in the field of industrial machinery repair. Our highly skilled service technicians offer custom rebuilding strategies, onsite repair, and unmatched service.

At Lindquist Machine Corporation, we take pride in our role as machinery rebuilders, dedicated to providing exceptional solutions to our valued clientele. With a rich history of expertise and dedication to quality, innovation, and customer satisfaction, we have established ourselves as a trusted partner in the industry. Our core focus lies in rebuilding a wide range of machinery, including CNC...

We are machinery rebuilders specializing in press rebuilding and repair plus clutch rebuilding and conversion. Our machine shop repairmen average 25 to 35 years of experience with all types of metalforming and manufacturing equipment. We can provide on-site service including new part fabrication.

At Betar, Inc., we pride ourselves on being expert machinery rebuilders, dedicated to providing top-tier solutions to our valued clientele. With a wealth of industry experience and a steadfast commitment to quality, innovation, and customer satisfaction, we have cemented our reputation as a trusted partner in the realm of machinery repair and refurbishment. Our primary focus revolves around the...

Welcome to Benning, where we specialize in rebuilding, repair, retrofitting, hand scraping and service on all types of precision metal working equipment. We provide services at our place or yours and machine size is never a factor. Some of the services available are spindle grinding, way surface repair, complete leveling service and much more. We’ve been servicing machine tools since 1972.

More Machine Tool Repair Companies

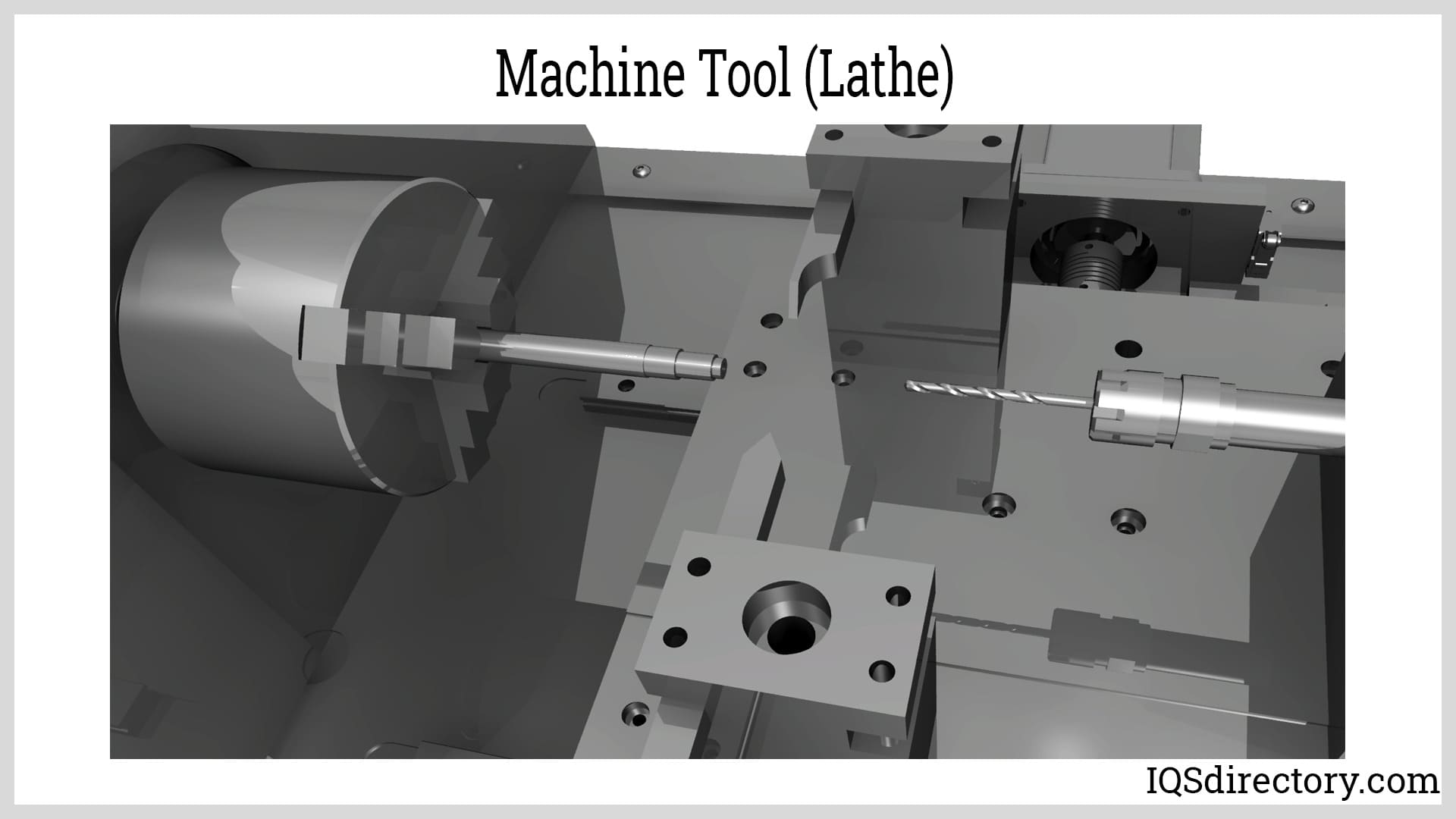

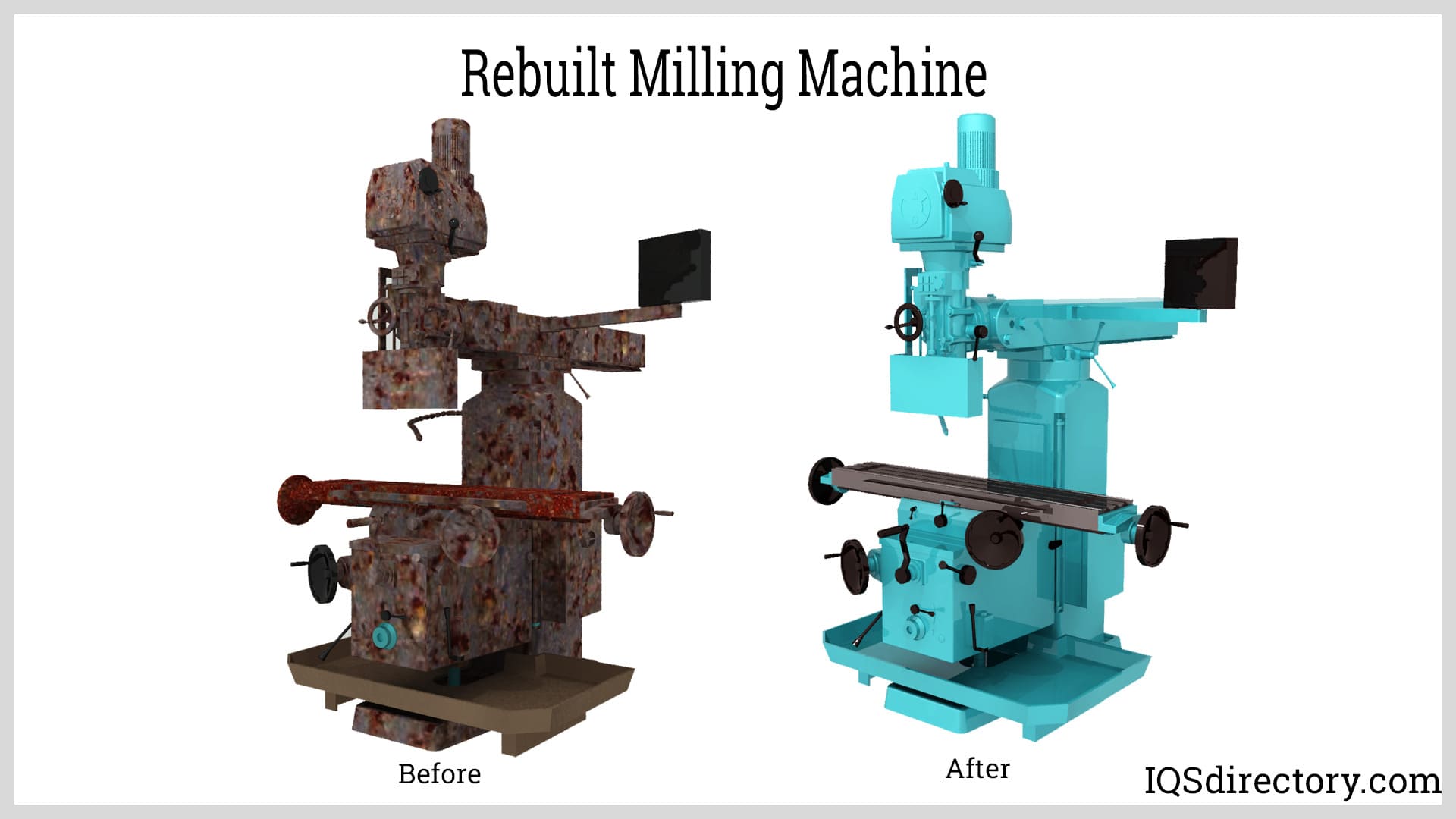

Machine tools must be able to remove metal from a workpiece while holding the cutting tools. A "down" machine tool is a problem that requires attention right away since it leads to decreased output, limited capacity, and lost income. Machine tool repair puts a malfunctioning or ineffective machine back in working order. Repairs are restoration work done when an asset breaks, is damaged, or ceases to function.

Signs That the Machine Tool Needs Repair

- Tool Age: Machine tools should be evaluated regularly to check for wear and tear and determine if they need to be fixed. The machine tool ages with time and frequency of use, which means that if it is used for an extended period, it will age, and if it is used more frequently, it will age faster. Machine tool inspection should be done every six months by a professional to get a heads-up on when to repair or change the machine tool.

- Strange Noises: Warning signals of a malfunction mainly come in the form of funny and unusual noises, making it easier to spot the faults in the machine tool. These funny noises should not be ignored, as they are crucial in saving both the machine and the tool.

- Difficulty of Use: If the machine tool is not functioning properly, it has been damaged somehow and is due for service. A machine tool that has stopped working due to being caught on something or for any other reason should be inspected first to avoid further damage. Likewise, using a machine tool that is misbehaving is a hazard to the operators.

- Obvious Buildup: When storing a machine tool for a lengthy period, it is ideal to clean it thoroughly to have it in good working condition for later use. However, a machine tool should be set aside and waiting for an evaluation from a specialist before being used when some type of buildup, such as rust, feed, or anything unidentifiable, has accumulated and clogged it.

Levels of Repair

The degree of failure producing an asset's dysfunction determines the extent of repair that is required. Two primary types of equipment failure exist.

- Partial Failure: The asset still works, but only to a limited extent. There are also possible security risks. Before the discovered problem causes the asset to fail, corrective measures can restore its health and functionality. In this case, despite the failure, the asset still functions somewhat. The apparatus is still operable, but it is either dangerous or ineffective. For instance, a motorist may drive while the air filter is unclean. However, he might notice that the air conditioning isn't as frigid as it once was or that the air quality is so bad that he starts to sneeze. In general, minor failures should be fixed as soon as feasible to prevent full breakdowns from occurring at inopportune times.

- Complete Failure: Most machine failures are due to the operator’s negligence and not paying attention to small signs. Repairing a machine tool from complete failure requires a lot of time, and the expense is quite high. However, the cost of unplanned downtime brought on by asset breakdown requires quick maintenance. A machine tool should not fail, as this would compromise the operator's safety.

Importance of Machine Tool Repair and Maintenance

- Keeps tools working better and longer

- Catch defects, dings, and other damage

- It prevents delays due to malfunctioning tools.

- Keeps employees safe

- Maximize tool investment

Advantages of Machine Tool Repair

- No planning is needed.

- Lower, short-term costs

- It is a simplified process; no extra equipment is needed for fault identification compared to maintenance.

- Less time is consumed.

- Increases machine tool life without the need for repair

Disadvantages of Machine Tool Repair

- If the potential faults are not protected, the system may sustain damage.

- When operations are paused, productivity and potential losses are reduced.

- Increases labor costs

- Faults can cause overall system failure, which creates an unsafe working environment.

Conclusion

A machine tool is a device used to manufacture components for various products using a subtractive cutting method. The four fundamental components of the manufacturing process are contained in machine tools. These components are an energy source for constrained relative motion and a way to secure the work, secure and orient the tool, and regulate the first two. Actions can be taken to restore an asset's functionality. In essence, machine tool repair involves fixing something that isn't functioning properly. Failure can occur in two different ways. Depending on the kind of asset failure, different levels of repairs may be needed.

Choosing the Proper Machine Tool Repair Company

To make sure you have the most constructive outcome when purchasing Machine Tool Repair from a Machine Tool Repair Company, it is important to compare at least 5 Suppliers using our list of Machine Tool Repair companies. Each Machine Tool Repair Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Machine Tool Repair company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Machine Tool Repair businesses with the same message.

Automation Equipment

Automation Equipment Car Wash Equipment

Car Wash Equipment Centrifuges

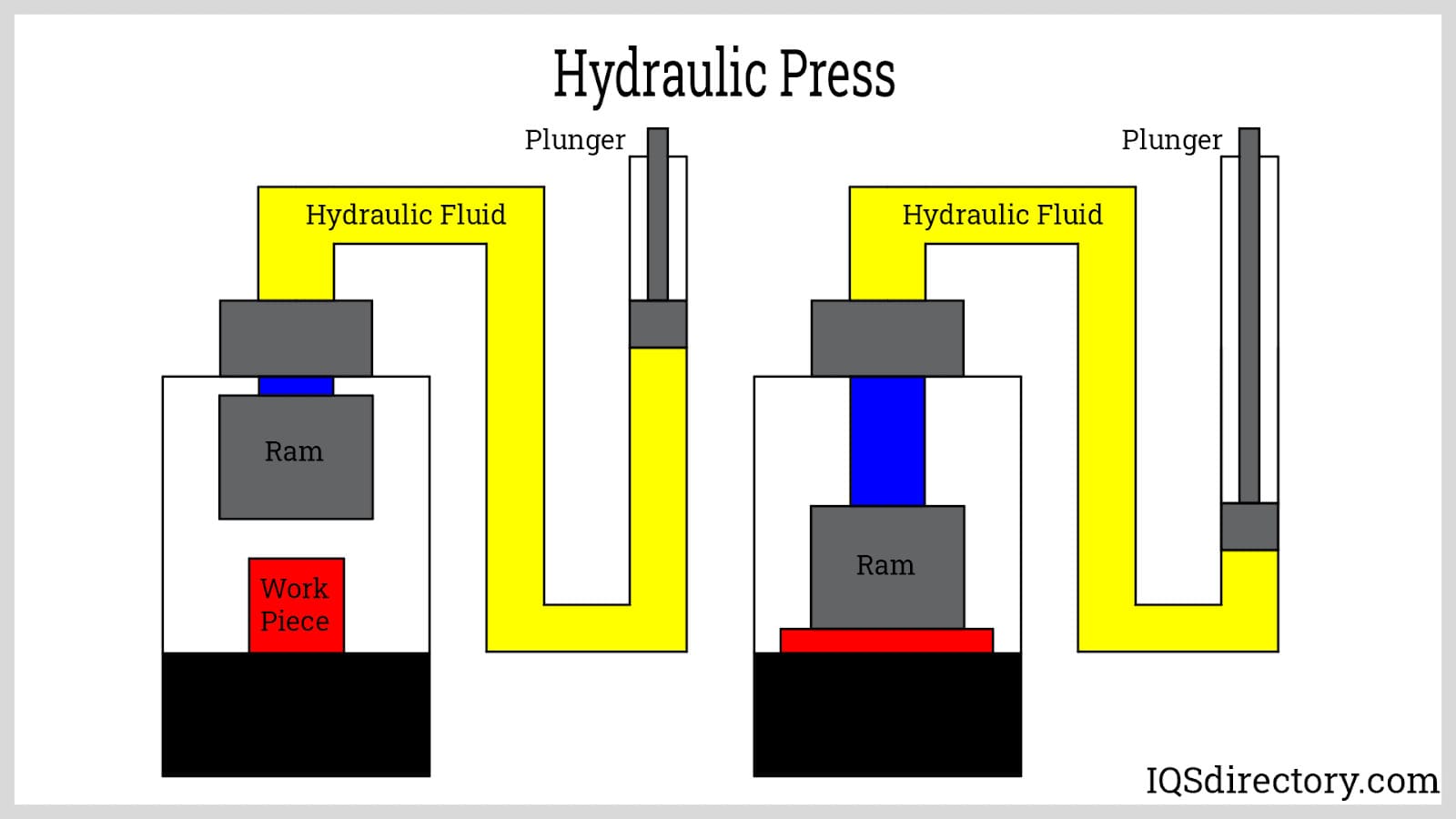

Centrifuges Hydraulic Presses

Hydraulic Presses Lasers

Lasers Machinery Rebuilders

Machinery Rebuilders Paint Finishing Equipment

Paint Finishing Equipment Tube Forming Machines

Tube Forming Machines Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services